Views: 30 Author: Site Editor Publish Time: 2026-01-29 Origin: Site

Elevate Your Footwear Manufacturing Efficiency with Top-Grade PU DP Shoe Mould from HuadongSoles!

PU Direct Pouring Shoe Mould, shortly named PU DP Shoe Mould, is a core equipment revolutionizing the footwear production industry, integrating shoe upper and sole forming in one step to create high-quality PU integral shoes with outstanding performance and cost advantages.

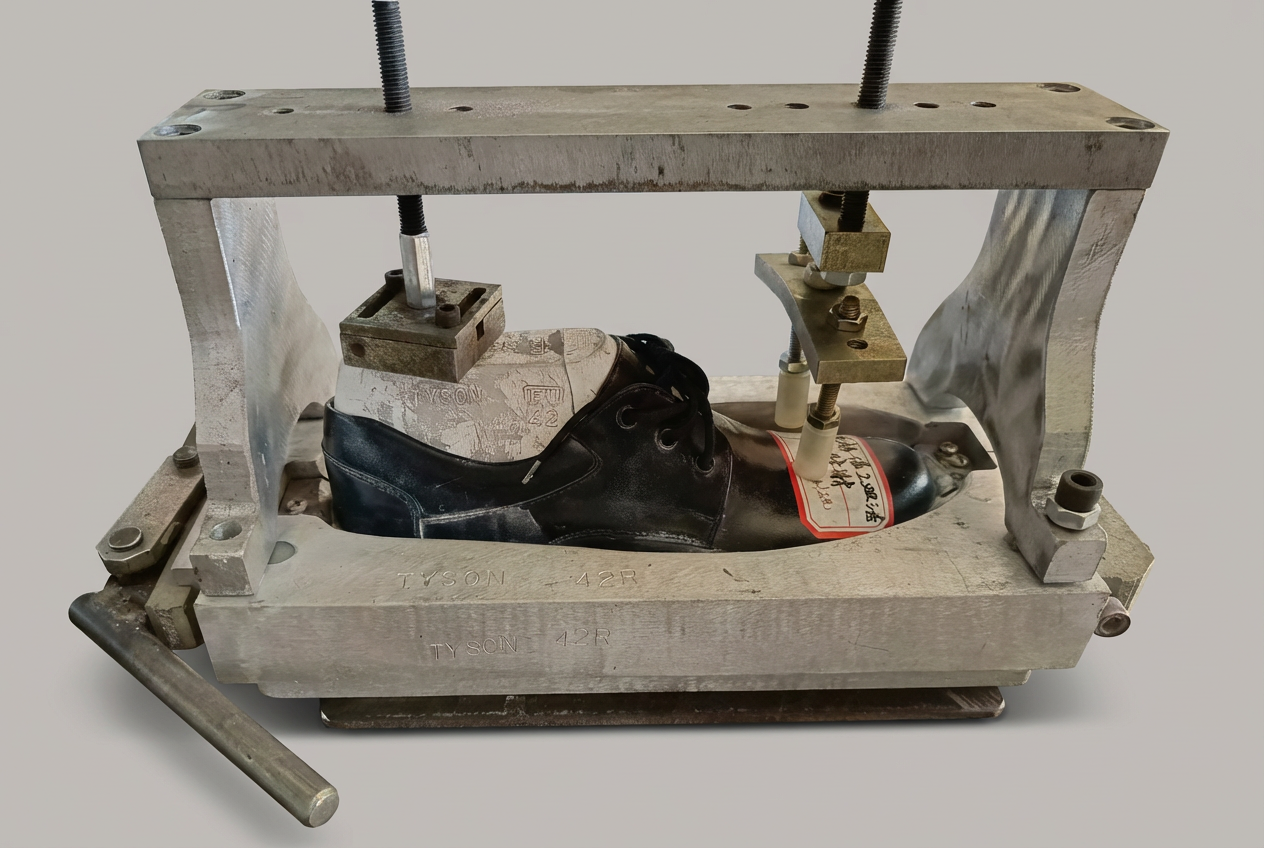

Core Structure of PU DP Shoe Mould: Stable & Precise for Perfect Forming

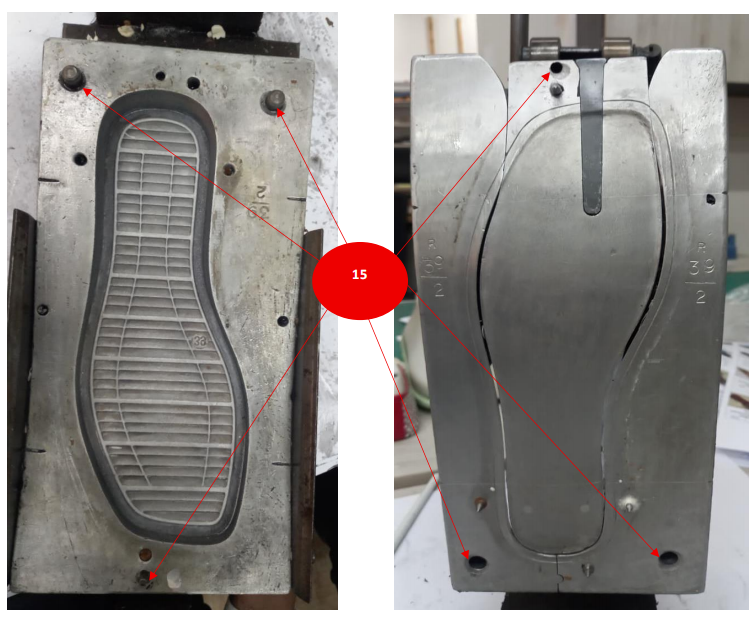

The high-quality PU DP Shoe Mould is scientifically composed of 4 key components, each playing an irreplaceable role to ensure precise shaping and consistent quality of finished shoes:

1. Bottom Mould: The base part to fix the overall shape of shoe sole, with customized patterns and anti-slip textures designed according to different shoe types, ensuring the sole meets wear-resistant and anti-slip requirements;

2. Middle Frame: Connects the bottom mould and upper cover tightly, seals the mould cavity to prevent PU raw material leakage during pouring, and controls the thickness of sole and the connection tightness between sole and upper;

3. Shoe Last: The core component to determine the shoe size, fit and wearing comfort, its accurate shape directly affects whether the finished shoe fits the foot perfectly, and it can be adjusted flexibly for different shoe sizes and foot types;

4. Upper Cover: Covers the shoe last and upper during pouring, presses the upper tightly to fit the shoe last and mould cavity, ensuring the upper adheres closely to the sole without gaps, and guarantees the overall neatness of shoe shape.

Global Application of PU DP Shoe Mould: Hot Demand in Emerging Footwear Markets

With the advantages of high efficiency and cost-effectiveness, PU DP Shoe Mould has been widely applied in footwear production around the world, especially gaining explosive popularity in emerging manufacturing countries in recent years.

Countries like Pakistan, India, Bangladesh, Egypt and Turkey, which are the core production bases of global mid-to-low-end footwear and are expanding their high-quality shoe production capacity, have imported large quantities of PU DP Shoe Mould. The reason lies in that this mould can perfectly match the production needs of multiple shoe categories, including daily-worn slippers and sandals, comfortable casual shoes, as well as functional single-density outdoor shoes and double-density outdoor shoes with strong support and wear resistance. These countries rely on PU DP Shoe Mould to improve production capacity, expand product categories and enhance the competitiveness of their footwear products in international markets.

Why Do Shoe Factories Prefer PU DP Shoe Mould? 4 Key Advantages That Can’t Be Ignored

Compared with traditional shoe-making moulds and processes, PU DP Shoe Mould has become the first choice for more and more shoe factories with its unique advantages, bringing tangible benefits to enterprises:

1. Moderate mould price: The cost of PU DP Shoe Mould is highly cost-effective, far lower than high-end injection moulds, and its service life is long (can be used for more than 100,000 times with proper maintenance), which greatly reduces the long-term equipment input cost of shoe factories;

2. Simple operation: The mould has a humanized design, no need for complex professional skills for operators, and the whole process from mould clamping, pouring to demoulding is easy to master, which shortens the training cycle of workers and reduces operation errors;

3. Low production cost of finished shoes: The PU direct pouring process realizes one-step forming of upper and sole, with material utilization rate up to 95% above, avoiding material waste caused by cutting and processing in traditional processes;

Save labor and streamline production: It completely eliminates the massive manual work and long production lines required by traditional cold bonding process (such as sole brushing glue, upper pasting, pressing and other links), reduces labor cost by 40%-60%, shortens the production cycle by 30% above, and greatly improves the overall production efficiency of shoe factories.

Application & Sales of PU Integral Shoes in Global Brands: High Popularity & Rapid Growth

PU integral shoes made by PU DP Shoe Mould are favored by global top footwear brands and consumers for their lightweight, wear-resistant, comfortable and durable features, showing a steady growth trend in global sales.

Well-known sports brands use PU DP moulds to produce outdoor shoes and casual sports shoes, the double-density soles made by the mould can balance support and comfort, meeting the needs of sports people for shoe performance; professional safety shoe brands adopt this process to make safety shoes with anti-piercing and anti-slip functions, which comply with international safety standards; meanwhile, fast-fashion shoe brands rely on the high efficiency of PU DP moulds to quickly launch new casual shoes and sandals, responding to market trends in time.

From the global market data, the annual sales volume of PU integral shoes has exceeded 2 billion pairs in recent years, with a year-on-year growth rate of 12%-15%, and the market share in outdoor shoes and casual shoes has exceeded 35%, becoming one of the fastest-growing categories in the footwear market.

HuadongSoles: Your Reliable Partner for High-Quality PU DP Shoe Mould

As a professional manufacturer with rich experience in PU DP Shoe Mould production, HuadongSoles has been focusing on the R&D and production of shoe moulds for many years, and has won the trust of shoe factories in more than 20 countries and regions around the world.

Rich production experience: We have mature production technology and strict quality control system, each set of PU DP Shoe Mould is carefully made, ensuring stable performance and long service life;

Professional shoe last development: We are good at developing customized shoe lasts according to customers' needs, combining ergonomic design to ensure the finished shoes fit the foot perfectly and improve wearing comfort;

One-stop optimization service: Our professional team can help customers optimize sole design according to their product positioning (such as anti-slip, wear-resistant, lightweight requirements), adjust the mould structure reasonably, and finally achieve the optimal effect of finished shoes;

Efficient after-sales support: We provide timely technical guidance and after-sales maintenance service, solving customers' problems in mould use and production process quickly, ensuring smooth production.

Choosing our PU DP Shoe Mould is choosing high efficiency, high quality and high profit, helping your shoe factory stand out in the fierce market competition.

FAQ: Below are some common Question to help you know better about PU DP moulds!

Q1: How long is the service life of our PU DP Shoe Mould, and can it meet large-scale production needs?

A1: Our PU DP Shoe Mould is made of high-quality mould steel and aluminum materials, with special surface treatment, the service life can reach more than 200,000 molding times, which is far higher than the industry average level, and can fully meet the long-term large-scale production needs of shoe factories, reducing the frequency of mould replacement.

Q2: Can Huadong customize PU DP Shoe Moulds according to our product design and size requirements?

A2: Of course! We support full customization service. Our professional team can design and produce corresponding PU DP Shoe Moulds according to your shoe style, size standard, sole thickness and other personalized requirements, and also optimize the design according to your actual production process to ensure that the mould is perfectly matched with your production equipment.

Q3: What is the delivery time of your PU DP Shoe Mould, and is there any after-sales support?

A3: The delivery time of standard moulds is 15-20 working days, and the delivery time of customized moulds can be negotiated according to the complexity of the design. We provide perfect after-sales support: if you encounter any problems in the use of the mould, our technical team will reply within 24 hours and provide online guidance or on-site maintenance services to ensure that your production is not affected.