Views: 37 Author: Site Editor Publish Time: 2026-02-04 Origin: Site

In the competitive footwear industry, comfort, durability, and performance are non-negotiable factors that drive consumer choices-and PU (polyurethane) insoles have emerged as a game-changer for shoe brands aiming to excel in these areas. While not the cheapest option on the market, PU insoles deliver unmatched value through their superior softness, resilience, and long-lasting comfort, making them a favorite among leading shoe manufacturers globally. Let’s break down what makes PU insoles stand out, their diverse applications, and why partnering with East China Shoe Sole is your best bet for high-quality, customized solutions.

Understanding PU Insole Materials: Types, Differences & Applications

PU insoles are not a one-size-fits-all product-their performance is determined by raw material formulations, which are tailored to specific footwear needs. Here are the most common types and their unique characteristics:

• Flexible PU Foam: Made with a soft, compressible formulation, this type offers exceptional foot contouring and energy return. It’s lightweight, shock-absorbent, and ideal for everyday casual shoes, sneakers, and walking footwear. While less abrasion-resistant than rigid alternatives, its comfort-focused design makes it a top pick for brands prioritizing wearability.

• Semi-Flexible PU: A balanced blend of cushioning and structural support, semi-flexible PU resists cracking and maintains shape even with extended use. It’s perfect for hiking boots, outdoor workwear, and all-terrain shoes-offering enough comfort for long walks while providing the stability needed for variable conditions.

• Expanded PU (EPU): Featuring a microcellular foam structure, EPU is ultra-lightweight with enhanced rebound and durability. It’s often used in premium athletic shoe midsoles, delivering superior underfoot comfort and energy absorption without adding extra weight. Though production costs are higher, its performance benefits justify the investment for high-end footwear lines.

• Polyester vs. Polyether PU: Polyester-based PU insoles offer better resistance to oils, heat, and abrasion, making them suitable for safety shoes and industrial footwear. Polyether-based PU, on the other hand, excels in moisture resistance and low-temperature flexibility, ideal for outdoor shoes used in humid or cold environments.

Why Shoe Manufacturers Are Choosing PU Insoles Over Cheaper Alternatives

While materials like EVA or PVC may have lower upfront costs, PU insoles provide long-term value that translates to happier customers and stronger brand loyalty. Here’s why demand is soaring:

• Unbeatable Comfort & Resilience: PU insoles mold to the foot’s shape for personalized fit, while their high rebound rate ensures they bounce back after each step-unlike EVA, which tends to collapse and lose cushioning after 3-6 months of use. This means shoes with PU insoles stay comfortable longer, reducing customer complaints and returns.

• Durability That Saves Money: PU resists wear, tearing, and hydrolysis (degradation from moisture) better than many alternatives. Even with frequent use, PU insoles maintain their performance for 6-8 months or more, lowering the need for replacements and improving the overall quality perception of your footwear.

• Versatility Across Footwear Types: From casual sneakers and luxury loafers to safety boots and orthopedic shoes, PU insoles can be customized to meet the unique needs of any product line. Their flexibility, slip resistance, and chemical resistance make them adaptable to diverse use cases-something cheaper materials struggle to match.

• Market-Driven Demand: Now customer are willing to pay more for comfortable, long-lasting shoes. A study found that 78% of footwear buyers prioritize comfort over price, and PU insoles directly address this need. By upgrading to PU, shoe manufacturers can differentiate their products in a crowded market and command higher price points.

Global Market Trends: PU Insoles in Leading Shoe Brands

The global PU footwear market is booming-valued at $5.4 billion in 2024, it’s projected to reach $11.72 billion by 2033 with a CAGR of 7.12%. This growth is driven by adoption from top brands worldwide:

• Athletic giants like Nike, Adidas, and Puma use PU insoles in their premium running and training shoes, leveraging EPU’s energy return to enhance athletic performance.

• Outdoor brands such as The North Face and Columbia rely on semi-flexible PU for hiking boots, balancing comfort and durability for outdoor enthusiasts.

• Safety shoe manufacturers partner with PU suppliers for polyester-based insoles that meet industrial standards for abrasion and chemical resistance.

• Luxury brands like Clarks and ECCO choose PU for its soft, premium feel, elevating the comfort of their dress shoes and loafers.

Asia-Pacific leads the market with over 85% of global footwear production, making it the hub for PU insole innovation and supply. For shoe manufacturers, this means access to high-quality, cost-effective PU solutions that align with global trends.

Should Your Shoe Factory Increase PU Insole Usage?

The short answer: Yes! If you want to stay competitive and meet evolving consumer expectations. Here’s the business case:

• Higher Profit Margins: Premium footwear with PU insoles can be priced 15-30% higher than those with EVA, while the incremental cost of PU insoles is minimal (typically 5-10% more per pair). This translates to stronger profit margins without alienating price-sensitive buyers.

• Reduced Returns & Warranties: PU’s durability means fewer returns due to worn-out insoles, saving your factory money on replacement costs and shipping.

• Brand Differentiation: In a market saturated with low-cost, low-quality options, PU insoles let you market your shoes as “long-lasting” and “comfort-focused”-key selling points that resonate with modern consumers.

• Future-Proofing: As sustainability becomes more important, PU insoles can be made with recycled materials or bio-based polyols, aligning your brand with eco-friendly trends (a feature cheaper materials often lack).

Partner With Huadongsoles: Your Trusted PU Insole Supplier

At Huadong, we specialize in manufacturing high-quality, customized PU insoles for shoe factories worldwide. With decades of experience in the footwear industry, we understand the unique needs of shoe manufacturers-and we deliver solutions that meet your exact specifications:

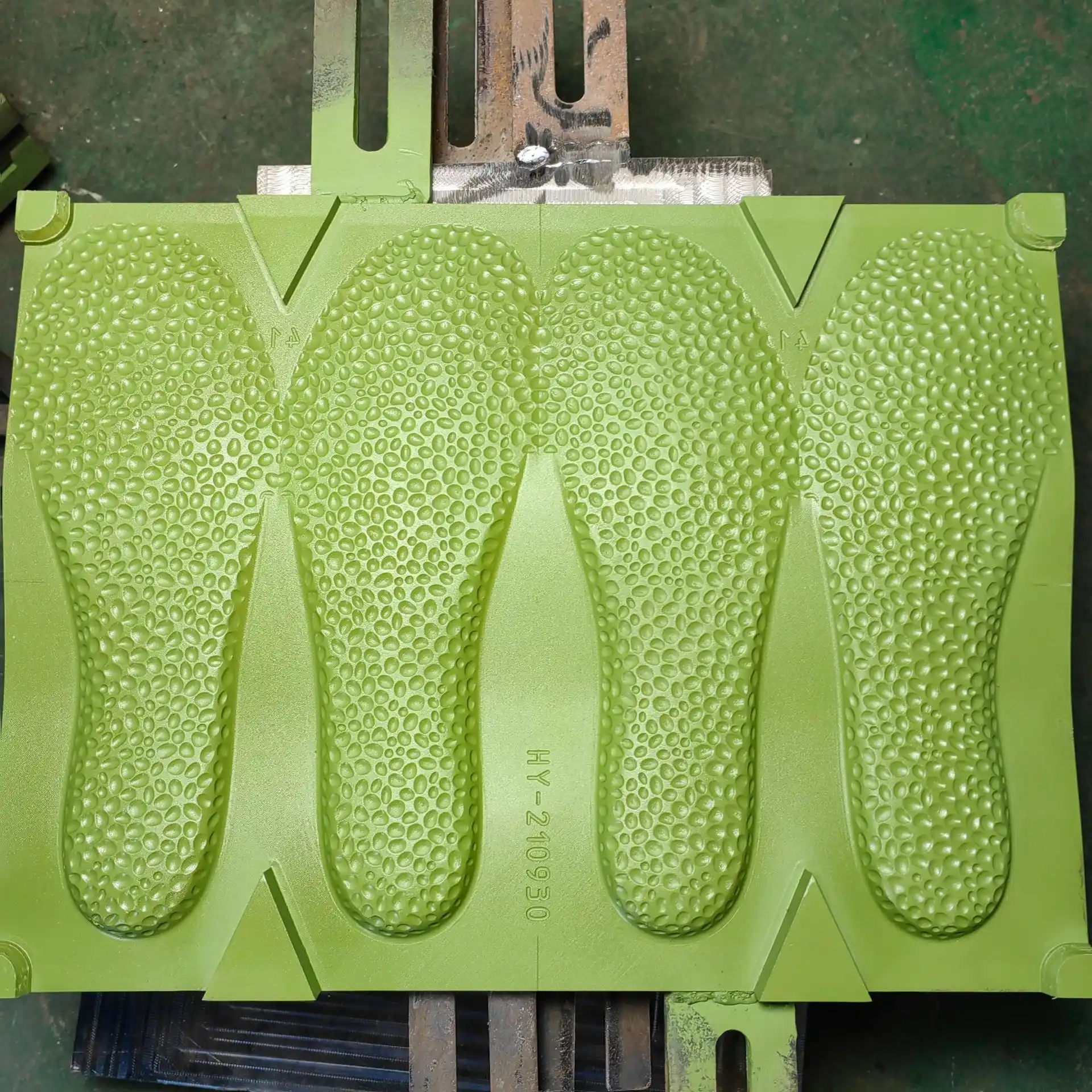

• Customization Expertise: Whether you need flexible PU for sneakers, semi-flexible PU for work boots, or EPU for premium athletic shoes, we tailor formulations, thicknesses, and designs to match your product line.

• Quality You Can Rely On: We use top-grade raw materials from trusted suppliers like BASF, Covestro, and Wanhua Chemical, ensuring our insoles meet global quality standards for durability, comfort, and safety.

• Scalable Production: Our state-of-the-art facilities can handle small-batch orders for new product launches or large-scale production for mass-market lines-with consistent quality and on-time delivery.

• Sustainable Solutions: We offer eco-friendly PU insole options, including recycled content and low-VOC formulations, helping you reduce your environmental footprint while meeting consumer demand for green products.

FAQ: Below are some common Question to help you know better about PU insoles!

Q1: Are PU insoles more expensive than EVA, and is the extra cost worth it?

A1: Yes, PU insoles are slightly more expensive upfront, but the investment pays off. PU lasts 2-3 times longer than EVA, reduces returns by up to 40%, and lets you price your shoes higher-resulting in better profit margins and customer loyalty over time.

Q2: Can PU insoles be customized for specific footwear types?

A2: Absolutely. We customize every aspect of our PU insoles-from material formulation (polyester vs. polyether, flexible vs. semi-flexible) to thickness, arch support, and surface texture-to match the unique needs of your footwear. Whether you need slip-resistant insoles for work boots or ultra-soft insoles for casual shoes, we’ve got you covered.

Q3: How do PU insoles perform in extreme conditions?

A3: PU insoles are highly adaptable. Polyether-based PU resists moisture and maintains flexibility in temperatures as low as -20°C, while polyester-based PU handles heat and chemicals well. Unlike EVA, which hardens in cold weather, PU retains its performance across diverse environments-making it ideal for global footwear markets.